Electrical data

Duty cycle

The data of the outputs for our electric motors are referred to S1 continuous duty, S3 75% or S6 75% periodic duty.

Nominal output

The outputs of Soga electric motors refer to the nominal output expressed in kW, that is the output mechanical power (P2) supplied by the motor through the shaft.

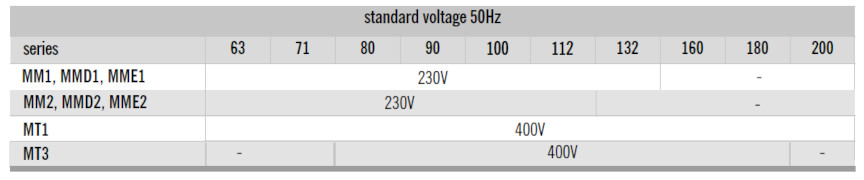

Frequency and voltage

All the technical data described refer to motors supplied at 50Hz. Our electric motors are available in single and three-phase version. IEC EN 60034-1 admits a voltage variation of ±5% with a maximum increase of temperature rise of 10°C.

Efficiency classes

Soga three-phase electric motors are available in standard single speed three-phase version and IE3 version.

Soga single-phase electric motors are available in standard single speed single-phase version and IE2 version.

Efficiency levels are tested in accordance with IEC 60034-2-1

According to EU2019/1781 regulation, in the output range 0,12 kW to 1, 000 kW, three-phase asynchronous motors for continuous duty operation have to ensure a minimum efficiency level IE3, while single-phase asynchronous motors for continuous duty operation have to ensure a minimum efficiency level IE2.

STANDARD VERSION SINGLE SPEED THREE-PHASE AND SINGLE PHASE

Soga motors in execution 2, 4, 6, 8 poles for extra EU markets or for EU markets used in applications not requiring high efficiency, are rated S6 75% (three-phase motors) or S3-75% (single-phase motors).

IE3 PREMIUM EFFICIENCY

Motors realized by Soga in 2 and 4 pole three-phase execution from 0,75 kW. They offer a high premium efficiency by ensuring a strong decrease in electricity consumption, allowing to recover the investment from the first year of use.

Thanks to their design optimized for high efficiency, IE3 motors ensure the windings a much lower thermal stress than motors with IE1 standard efficiency, allowing a longer motor life.

For IE3 models, executions different from the standard 50Hz may change variations in the efficiency levels.

IE2 HIGH EFFICIENCY

Single-phase motors realized by Soga in 2 pole execution from 0,18 kW. They offer a high efficiency by ensuring a strong decrease in electricity consumption, allowing to recover the investment from the first year of use.

Thanks to their design optimized for high efficiency, IE2 motors ensure the windings a much lower thermal stress than motors with IE1 standard efficiency, allowing a longer motor life.

For IE2 models, executions different from the standard 50Hz may change variations in the efficiency levels.

60Hz use

The standard frequency for Soga motors is 50Hz. Standard three-phase motors can also operate at 60Hz. On request we can manufacture motors with special voltage.

Insulation classes

Soga single and three-phase motors in standard execution are Class F insulated.

IE3 premium efficiency motors (three-phase) and IE2 high efficiency motors (single-phase) are Class F insulated with temperature rise Class B. Motors in Class H are available on request.

Windings treatment and post-treatments systems

Primary processes applied on stator windings for Soga motors are the following:

- Impregnation by dip with water-based varnish: treatment for single-phase and three-phase motors up to size EC132. Windings are dipped in an open tank containing water-based varnish (single-component).

- Impregnation by dip with polyester resin: treatment for three-phase motors from size IEC132 up to IEC200. Windings are dipped in an open tank containing insulating polyester resin (single-component) while an active and constant check of the temperature is also applied.

- VPI vacuum encapsulation with epoxy resin: it is a treatment on request. The epoxy resin (single-component) is applied in autoclave through VPI (Vacuum Pressure Impregnation) system in aim to eliminate any moisture, air and gas in the windings. It is suitable for high voltage applications.

- Vacuum encapsulation with bi-component resin: treatment on request through epoxy bi-component resin, recommended for rotating electrical machines used in extreme contexts and, more generally, when the priority is to ensure the highest reliability level of the windings, for instance in automotive, wind and railway industry.

Always on request, on windings which have been previously impregnated, it is possible to apply tropicalization process on stators as a post-treatment, when the motors are used in high moisture (>95%) and saline environments (marine applications).

As a special execution we can also supply windings with UL1446 insulation system.

Use with inverter

The standard series of our motors starting from size IEC112 is suitable for use with inverter, being equipped with phase separators on the end windings.

Motors with this execution can also be realized on sizes below IEC112, on request.

Testing

Each motor is tested directly in our production lines. Our testing room and staff are available to customers who want or need to do further tests on custom-made motors manufactured by Soga, for applications requiring this such as railway.

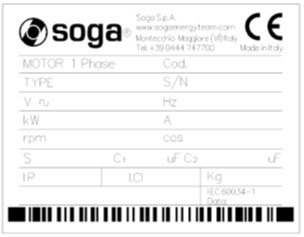

Motor plates

Soga motors are equipped with metal plates or stickers describing the main electrical data.