FOCUS LOW CENTER

INDUCTION MOTORS

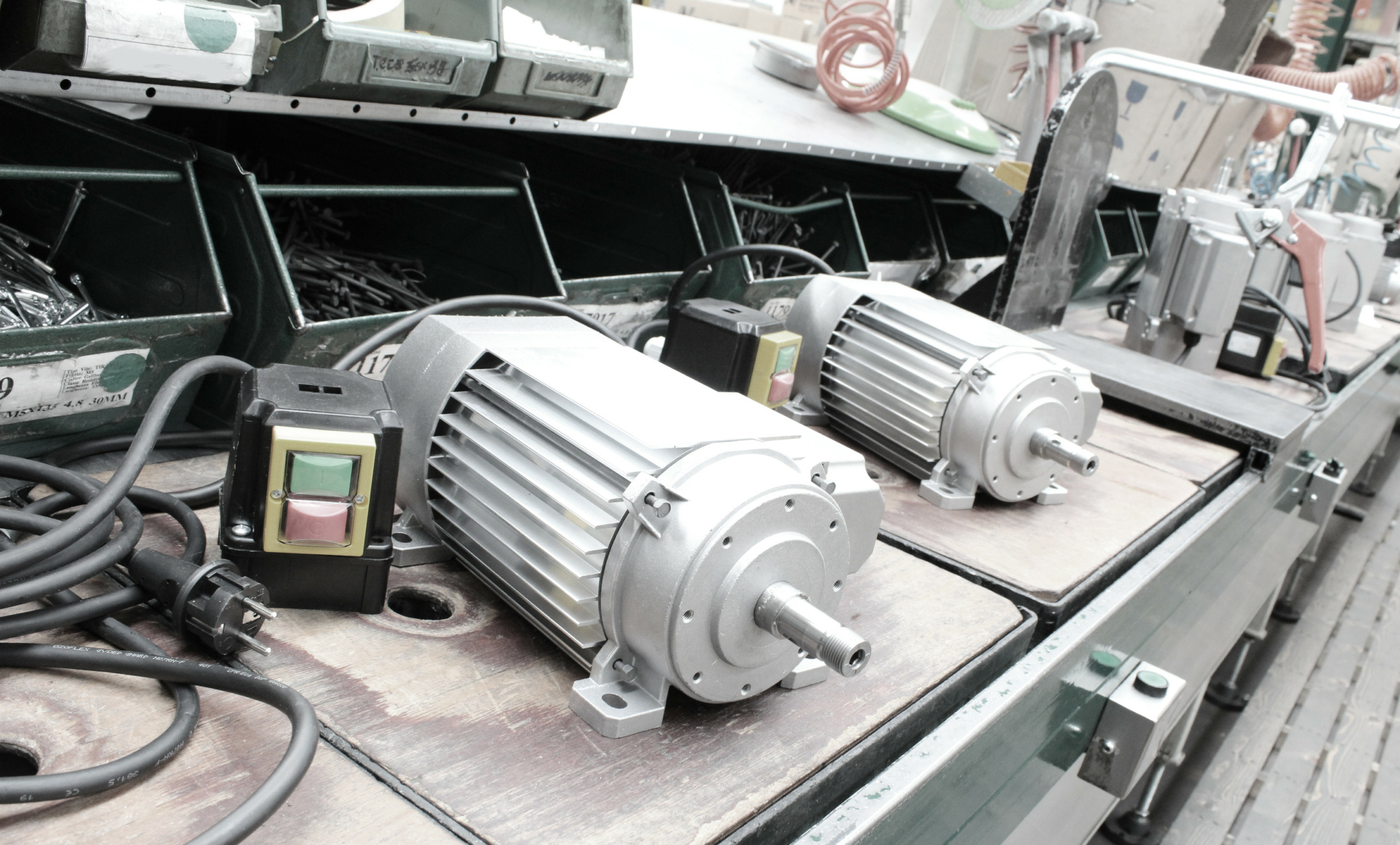

Low center electric motors are a specific type of induction motors. They are used for their compact size in applications where space-saving is a key factor.

COMPACT & POWERFUL

Low center asynchronous motors base their name on the frame size which, at same output, is reduced compared to asynchronous IEC motors.

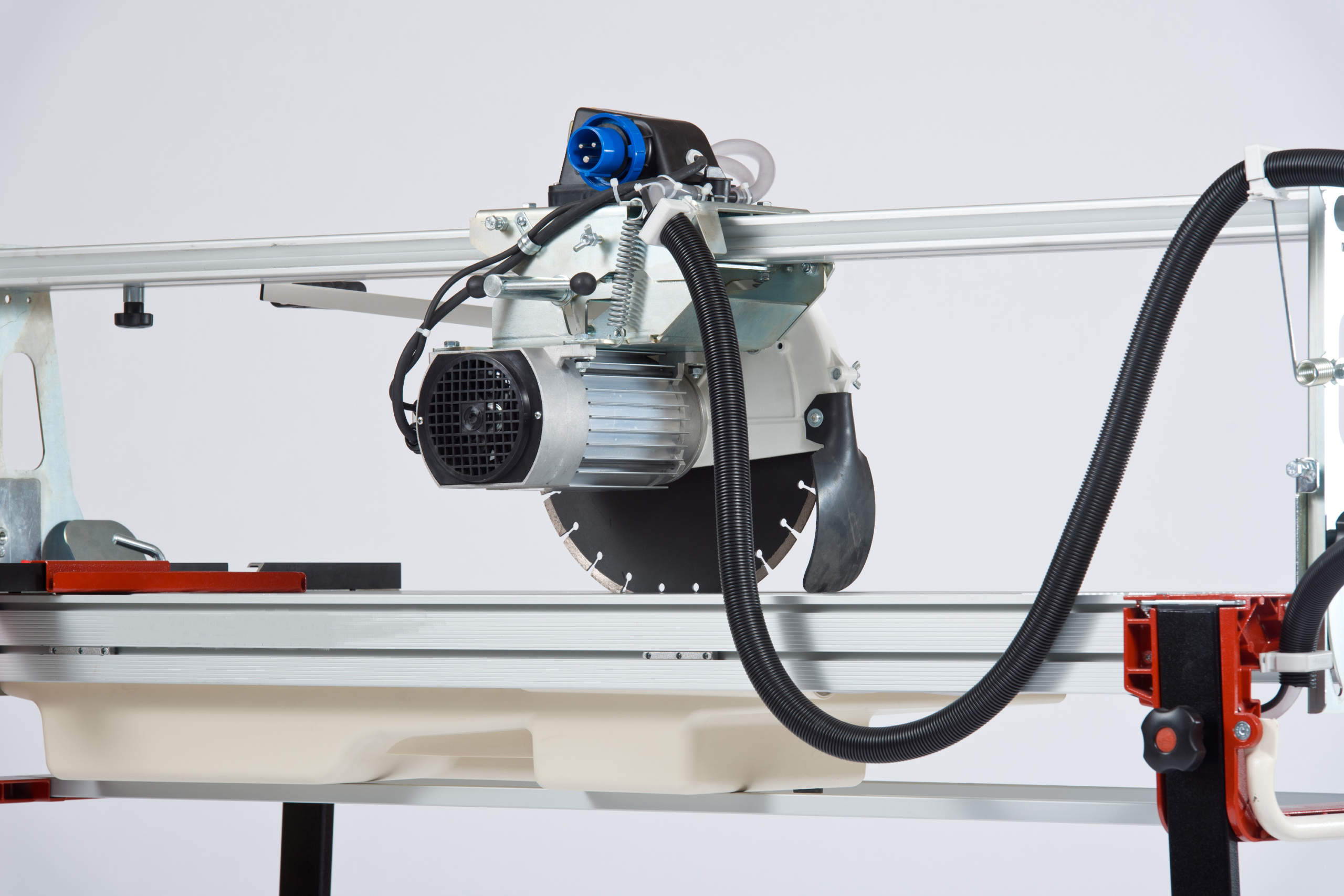

Compactness makes them the right solution whenever space-saving in motors dimensions is a relevant issue. Listing bench saws for wood and tiles cutting up to industrial milling machines for marble and granite, there are many machineries where low center motors find their place.

The most common sectors:

Cutting

Milling

Drilling

Grinding

The applications where low center motors are used have typically an intermittent duty type (S6-40% or S6-60%) according to which SOGA motors are suitably dimensioned.

S6 intermittent duty determines a higher torque density than IEC motors.

Download the catalogue to see SOGA motors complete electrical and mechanical data

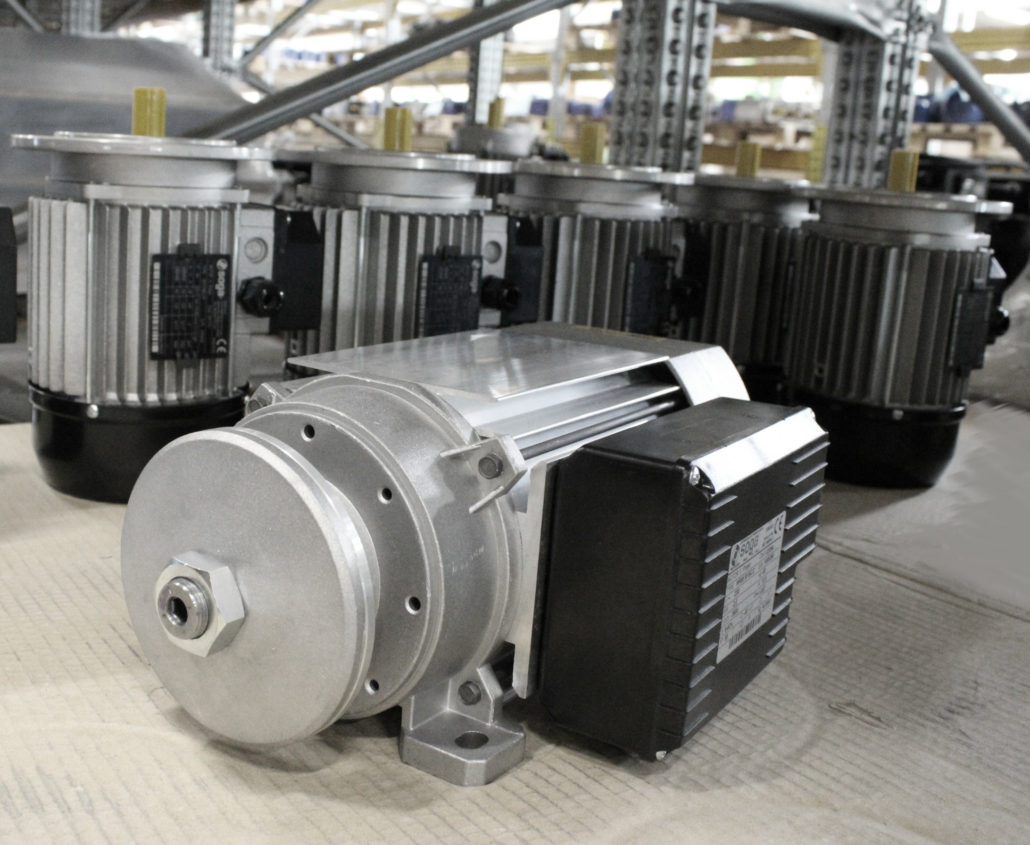

SOGA low center motors are supplied with or without blade-holding disks.

In the standard version they are equipped with 2 aluminum blade-holding disks (cast iron on the biggest size MR107). This direct-drive coupling is very appreciated by cutting machines manufacturers as it allows the machine blade to be mounted directly on the motor shaft: the assembly is much quicker and easier.

Such a solution also allows to avoid the pulley, with further reduction of production costs and a more linear and optimized structure of the full machinery.

In addition, the reduced size determines the blade to penetrate with greater depth of cut, helping to make the machinery much more performing thanks to more complete workings.

A STRONG RANGE

Low center motors are a specific line of products for SOGA® division: MR Motori Ribassati.

Models on catalogue are 39 divided in 6 series depending on the size (MR58, MR65, MR71, MR80, MR93, MR107) with outputs ranging from 0,75 kW to 18 kW (S6 duty).

SOGA offers many possible executions to give the customer a wide choice: single-phase and three-phase models, executions 3000 rpm, 1500 rpm, 1000 rpm.

Models have IP55 protection degree. MR107, very used for stone processing, is realized in IP65 to ensure total protection against water and dusts also thanks to the presence (drive-end position) of a zinc-plated steel labyrinth, two O-rings and a seal-ring. Moreover, specific gaskets are placed between the shields and the motor housing.

SOGA low center motors are Made in Italy, manufactured since 1994 inside our plants in Montecchio Maggiore.

Our production sites are ISO9001 certified and managed by Lean Production through latest generation equipment and processes.

CUSTOM-MADE MANUFACTURING

Upon the customer’s request, it is possible to customize each model as well as to design special, totally out-of-standard versions.

Some possibilities:

Feet (on MR5 series)

Right thread with anticlockwise shaft rotation

Special shafts and flanges

Special voltages and frequencies

Slowering-speed brake

On/off switches, special switches

UL/CSA insulation system.

The motors equipped with brake are some of the most required versions starting from MR65 series. Safety and technical execution become one single feature.